STUFFING BOX LANTERN RING

Lantern Rings Dimensions

| INCH | ||

|---|---|---|

| 1/4" x 5/16" | 1/4" x 3/8" | 1/4" x 1/2" |

| 5/16" x 7/16" | 5/16" x 5/8" | |

| 3/8" x 1/2" | 3/8" x 3/4" | |

| 7/16" x 9/16" | 7/16" x 7/8" | 7/16" x 5/8" |

| 1/2" x 5/8" | 1/2" x 1" | 1/2" x 11/16" |

| 9/16" x 11/16" | 9/16" x 1" | |

| 5/8" x 3/4" | 5/8" x 1" | |

| 3/4" x 7/8" | 3/4" x 1" | |

| 7/8" x 1" | ||

| 1" x 1" |

| METRIC | |

|---|---|

| 7,6x11,4 | |

| 9,0x 13,2 | 9,0x19 |

| 9,4x13,2 | |

| 10,5x 14,3 | 10,5x22 |

| 11,1x15,6 | |

| 12,1x17 | 12,1x25,4 |

| 12,6x17 | |

| 13,5x19,2 | |

| 14,2x19,2 | |

| 15,2x20,6 | 15,2x31 |

| 17x22,1 | |

| 18,1x22,1 | 18,1x38 |

| 19 x23,8 | |

| 20,8x25,2 | |

| 23,5x28,2 |

Specialized in

Lantern Ring

A lantern ring is used to supply or extract different media to or from the stuffing box. Lantern Rings, also well know by Universal Seal Cage, are usually in the center of every compression packing set in a centrifugal pump. They are simple components, but get something wrong when selecting, installing or operating them, and big problems may occur in the stuffing box. A lantern ring is placed between packing rings in each packing set and extends the life of the packing, stuffing box and shaft. Ultimately, lantern rings increase the life span of the pump system.

Do you need quick help or have questions?

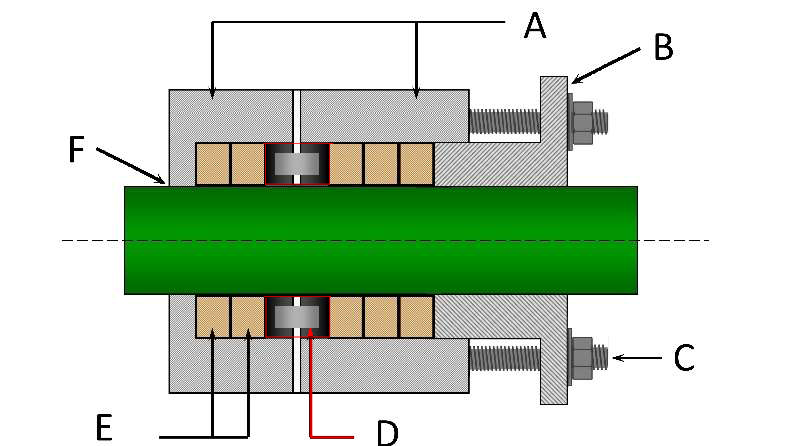

LANTERN RING POSITION

General Stuffing Box Arrangement

A: Stuffing Box Area

B: Gland

C: Gland Stud Bolts and Nuts

D: Lantern ring

E: Packing

F: Throat

Lantern Ring Purposes

PTFE Lantern rings serve three purposes: protection, cooling and lubrication. They protect the stuffing box and the installed packing by providing an access point for flush water. If process fluids or other contaminants enter the stuffing box and are not removed by flush water, several problems occur, including:

• damaged or destroyed packing

• shaft or sleeve damage

• stuffing box wear

A lantern ring also gives the stuffing box an outlet to assist with cooling. It allows the system to avoid being completely closed off and assists in mitigating overheating. The final lantern ring purpose is lubrication. Compression packing causes friction along the shaft and stuffing box walls or casing.

Fluid entering through the lantern ring lubricates the packing. The liquid reduces friction, limits the wear of the machine’s parts and decreases heat within the system.

Lantern Rings Material

| PEEK Strengths | PEEK Weaknesses |

|---|---|

| Tensile strength, elongation and wear properties | Not suitable for applications involving nitric or sulfuric acid |

| Chemical resistance | More costly |

| Withstands long exposure to high pressure, water and steam | Difficult to process |

| Low flammability | |

| Resistant to gamma radiation | |

| Continuous use up to 500F |

| PTFE Strengths | PTFE Weaknesses |

|---|---|

| Broad chemical resistance | Creep and cold flow |

| Nonflammable | Relatively soft |

| Low-temperature flexibility | Low thermal dissipation |

| Low coefficient of friction | Poor dimensional stability |

| High-temperature stability | High material shrinkage |

| Easy to process | Low rigidity |

| High-frequency resistance | Low electrical conductivity |

About Us

Why we are

the best

Machining & Processing

Each material has unique performance, we have mastered the characteristics of the material, so as to process precision products, such experience and technology accumulation, can produce parts according to customer requirements.Now, our team is ready to help you meet your needs.

Lantern Ring Installation

Most packing sets have five packing rings. The lantern ring can be inserted after the second or third packing ring is installed. This all depends on where the flush port of the stuffing box is located. To ensure that the lantern ring is installed correctly, insert a small object through the flush port and feel the lantern ring.

Once this is done and all the packing rings and packing follower are installed, end users should install the proper flush setup and start flushing the stuffing box. For many reasons, starting the flush before operating the pump is important. One reason is to ensure that flush water is moving through the lantern ring and into the stuffing box correctly.

Care must be taken to ensure the lantern ring’s fit around the shaft is correct. Most lantern rings have a larger fit on the inside diameter and a tighter fit on the outside diameter, so frictional heat is not an issue.

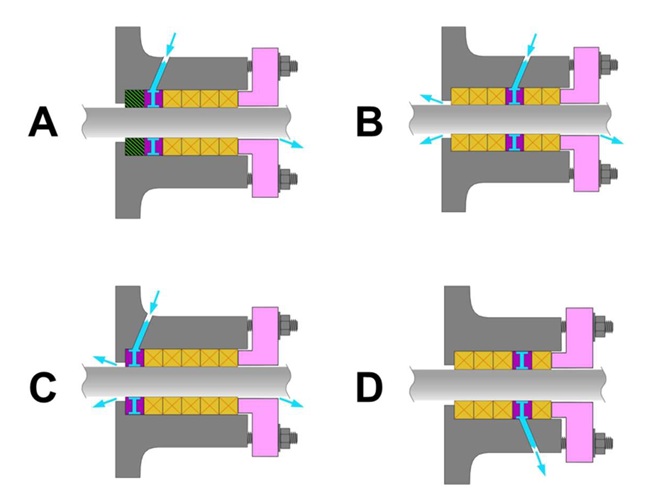

In the case of hard and abrasive media like slurry or river water in example A, a spacer ring can be installed at the bottom of the housing to reduce the clearances and to prevent larger solids from entering the stuffing box. Then the lantern ring is placed directly behind the spacer and flush water can be applied as a barrier fluid.

Example B shows the configuration for crystallizing media such as sugar, paints or plastics. Here the first three packing rings seal against the media and the flushing medium provides a barrier against the crystallizing fluid. The two packing rings on the gland side act as a secondary seal to minimize leakage from the flushing medium.

In the arrangement in example C the lantern ring is placed directly at the bottom of the stuffing box to flush with an inert gas which acts as a barrier against potentially explosive or toxic media. The following packing rings act as a safety seal.

In example D the lantern ring is used for leakage extraction in case of special or expensive media which can be re-directed into the production process.

There are also arrangements with two lantern rings in the stuffing box. For example, in high speed rotary pumps one lantern ring can be used for the supply of cooling water and the other one to extract the flush water again. But in this case the stuffing box length has to be fairly long.

Lantern Ring Price

Contact

Sunholly Material Co.,Ltd.

No. 130 , Jiushui Rd,

Qingdao 26600, CN

Whatsapp:+8618866423863

Wechat: +86 13061406946

e-mail: info@sunholly.com

Touch With Us

Monday - Friday

06:00 AM - 10:00 PM

Saturday - Sunday

08:00 AM - 08:00 PM

+86 188 6642 3863